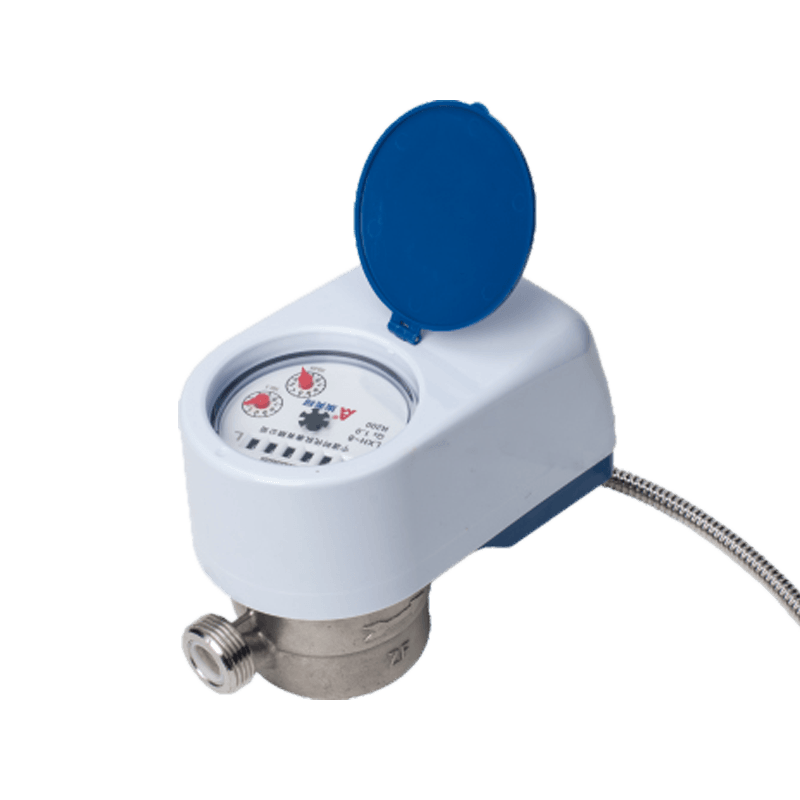

Working Principle of Photoelectric Water Meters

1. Photoelectric Direct Reading Encoding Structure

A photoelectric sensor (phototube or photodiode) is installed on the meter's dial wheel or rotor. Each digit is optically identified through a light hole or reflective barcode. A light source emits a beam, which is blocked or reflected as the dial wheel rotates. The sensor captures the changes in light intensity and converts them into an electrical signal, thus directly digitizing the mechanical reading.

2. Signal Acquisition and Processing

The collected photoelectric signal enters the built-in microprocessor for digitization, noise removal, and calibration, generating the corresponding metering data. This process only consumes power when a read command is triggered, resulting in extremely low power consumption and ensuring metering accuracy even in power outages.

3. Dry-Type Construction and Protective Design

The dry-type (battery-free) structure ensures that the photoelectric unit is powered only during reading, avoiding the lifespan limitations of traditional battery-powered water meters. The housing is made of protective material, dustproof and waterproof, ensuring stable operation of the photoelectric components in harsh environments.

4. High Accuracy and Error Suppression

Direct optical reading of the digit wheel eliminates pulse accumulation errors and achieves zero-error transmission. The photoelectric sensor's high sensitivity to changes in light intensity allows it to maintain accurate metering even under low flow conditions.

How do photoelectric water meters achieve remote automatic meter reading?

1. Communication Module and Bus Interface

The water meter integrates an RS-485 or M-BUS bus communication module, supporting wired data transmission. Power and signal transmission are shared via a two-core or four-core cable, simplifying wiring and improving interference resistance.

2. Data Collection and Concentrator

The reading command is sent by a host computer or concentrator. Upon receiving the command, the photoelectric unit immediately reads the mechanical digits and transmits the electronic data back to the collector. The collector can connect to up to 64 water meters, and multiple collectors are aggregated through the concentrator for centralized management of large-scale data.

3. Remote Transmission and Platform Integration

The aggregator uploads collected water consumption data to a cloud platform or local management system via mobile networks (such as 4G/5G) or dedicated lines. The platform stores, analyzes, and visualizes data, supporting real-time monitoring, abnormality alarms, and historical queries.

4. Low-Power Trigger Operation Mode

Since the photoelectric unit is powered only during reading, overall power consumption is extremely low. This allows metering integrity to be maintained even during extended periods of power outages, ensuring that remote meter reading is not affected by power outages and improving system reliability.

English

English 中文简体

中文简体